HVAC and water heating

Based on early reACT energy analysis, it was determined that approximately 3000 kWh/yr of the total 8000 kWh/yr electrical energy demand was consumed by home heating, cooling, and hot-water production, even with state-of the art LG variable refrigerant flow (VRF) heating/cooling and heat-pump water heater (HPWH) units and a Zehnder energy recover ventilation unit, equipment which all is currently installed in reACT.

Extensive research by the HVAC team in the potential benefits of preheating and precooling air sent to the VRF outdoor unit (OU) demonstrated significant improvements in performance; for example, a 10-20% increase in the cooling efficiency with as little as a 4 K temperature decrease depending on the ambient temperature. Because of the delay in defrosting operations, preheating the outdoor air demonstrated an even more dramatic effect at ambient temperatures neat freezing. The HPHW energy consumption was also shown to demonstrate the benefits of preheating air fed to its OU.

This approach to increasing the efficiency of HVAC and heat-pump water heaters fits perfectly with one of reACT’s signature design features: its courtyard and the ability to use it as a thermal resource. As such, air that is warmer than ambient outdoor can be generated in the courtyard by closing the skylight vents during the day and sending the relatively warm air to both OUs of the VRF and HPWH.

Likewise on hotter days with cool mornings, the courtyard can be pre-cooled in the early morning and the relatively cool air can be harvested later to precool the VRF OU air feed. Both OUs would be housed in reACT’s attic with a damper control system to switch between the two modes of operation. An added architectural benefit results from hiding the two OUs in the enclosed attic.

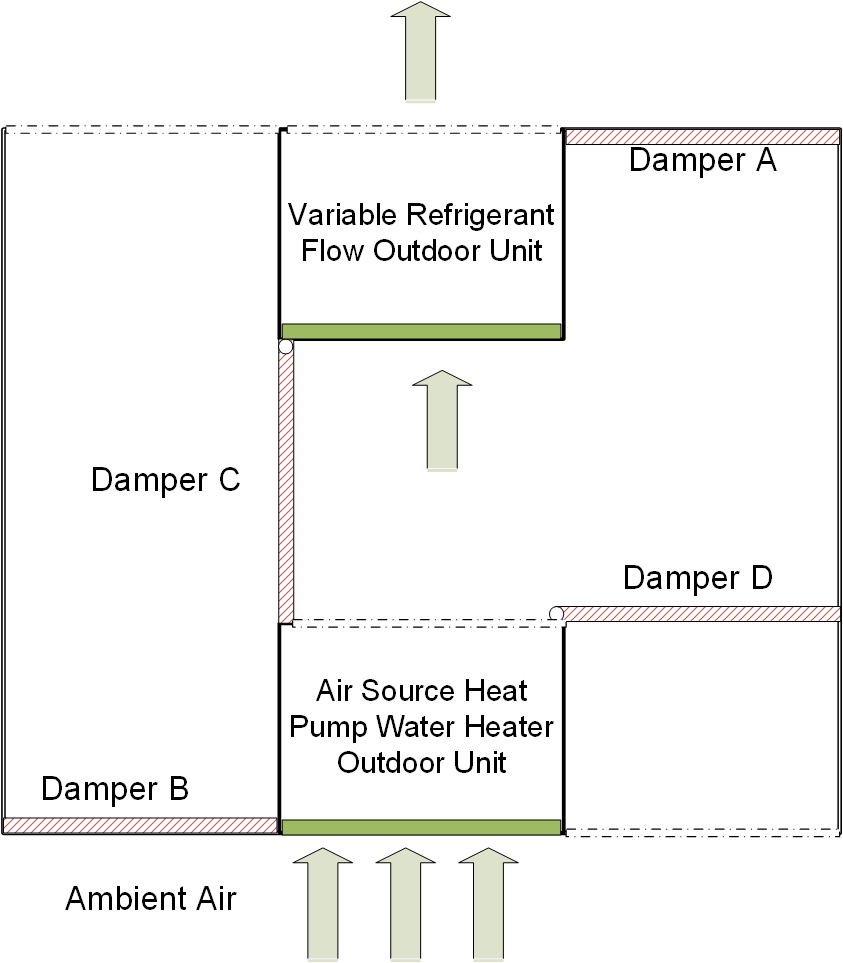

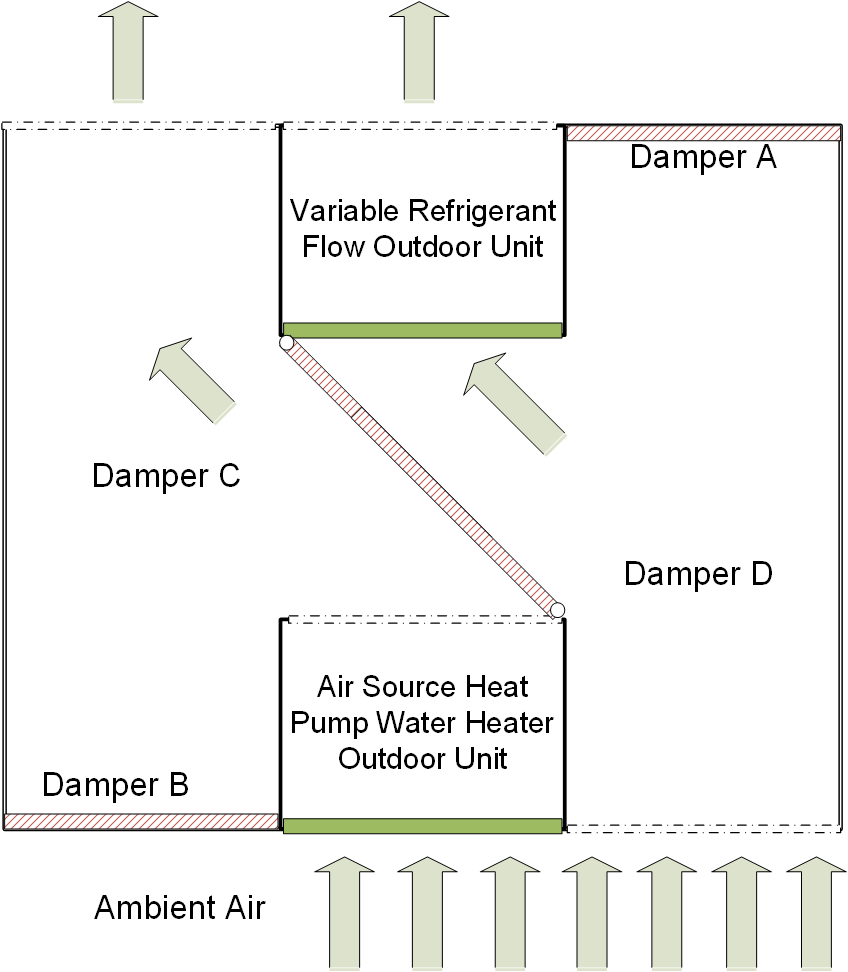

A final design iteration combines both OUs by directing the air to flow through each in a sequential fashion – consider the configuration shown in Figure 1 (left). In this arrangement, warm courtyard air flows first through the HPHW OU, is cooled, and then flows though the VRF OU to improve its cooling performance. This constitutes the cooling season (summer) mode of operation. In heating season, the cooler air from the HPHW OU is rejected and warm courtyard air is directed to both OUs through the rearrangement of the dampers shown in Figure 1 (right).

Figure 1. Cooling season damper (left); damper positions for heating season (right).

reACT integrates an energy recovery ventilation heat exchanger, and 2 state of the art heat pump systems: 1 for space air conditioning and 1 for our water heater. Our innovations feature an ultra energy efficient attic configuration where our heat pumps utilize solar thermal energy from our courtyard. In the warmer months, our heat pump hot water heater precools the air in which our air conditioning heat pump rejects heat. In the winter time, our solar gain from the courtyard in distributed equally to the hot water and air conditioning systems. This is accomplished using unique flag stick damper control.